What Are Cut Points and Why Do They Matter?

Whether you choose to order a custom length strip, or make in-field length modifications, precise strip measurements are critical in the overall performance and appearance of the LED light source.

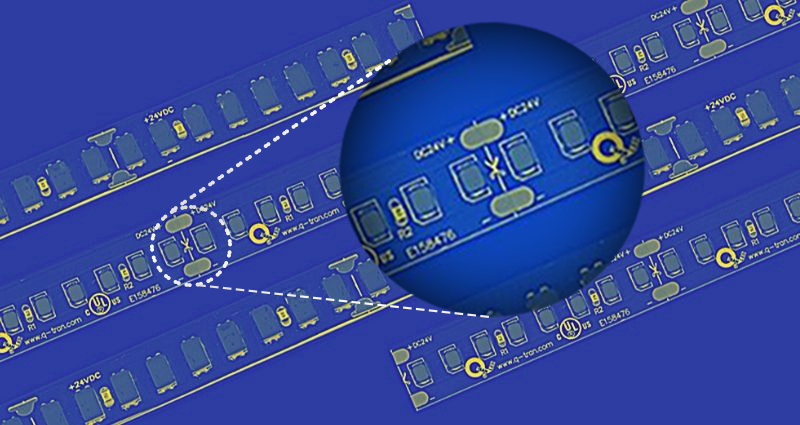

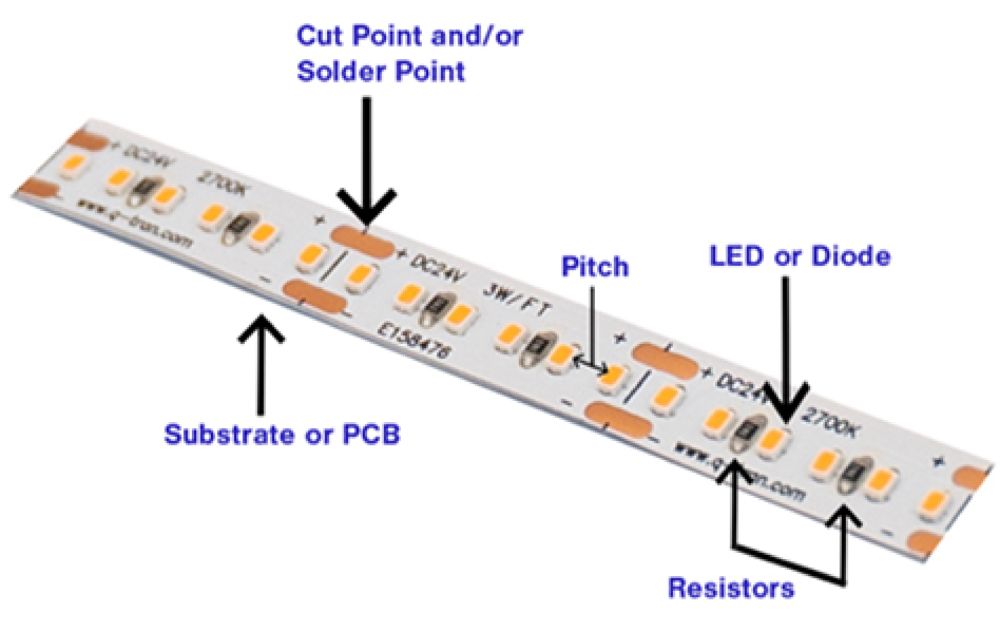

Linear LED strips can come in reels anywhere from 16' to 1000' in length and can modified in-field by hand to the desired length using standard scissors along the indicated cut lines or solder points. These marked cut lines are what's known as "cut points".

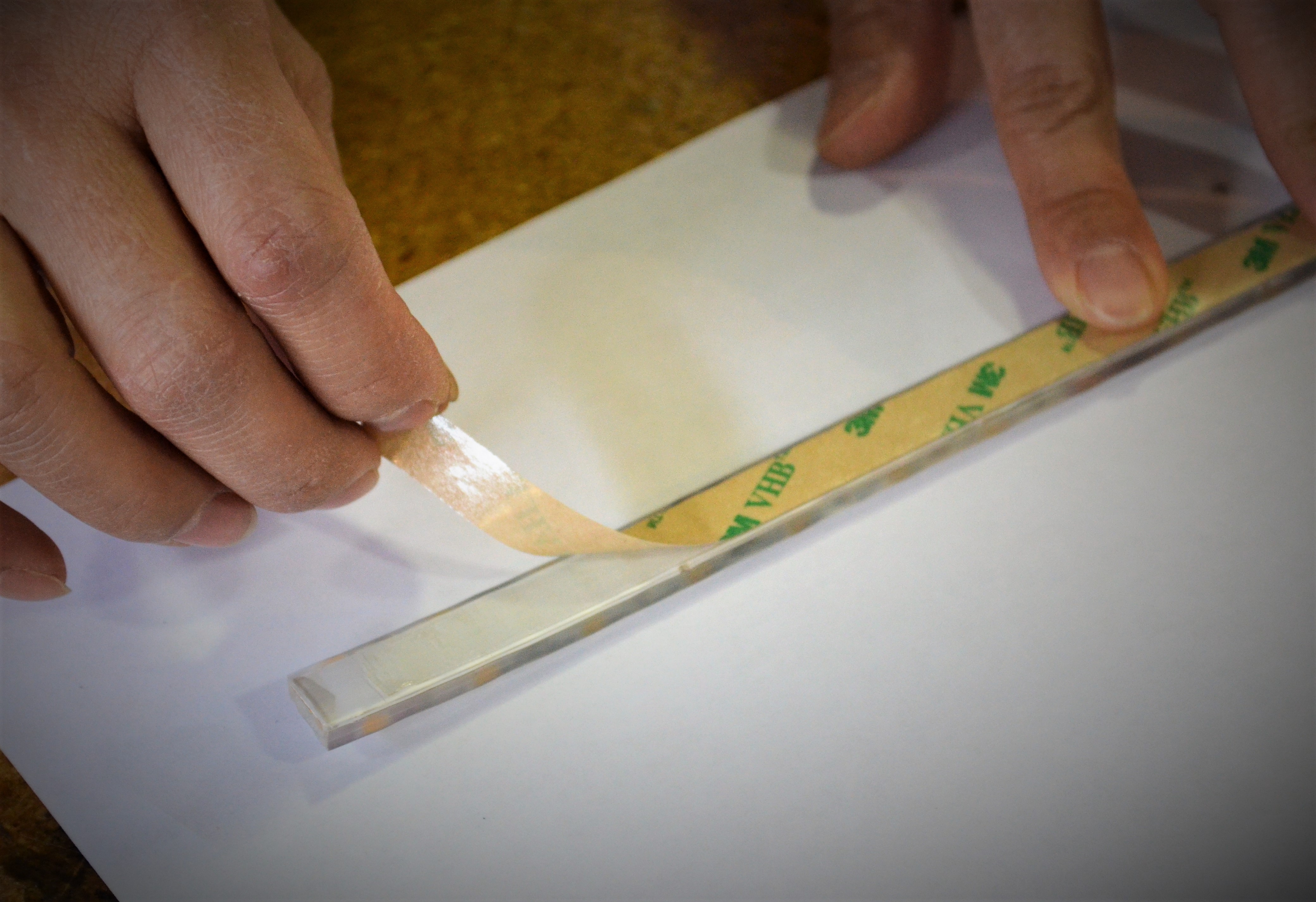

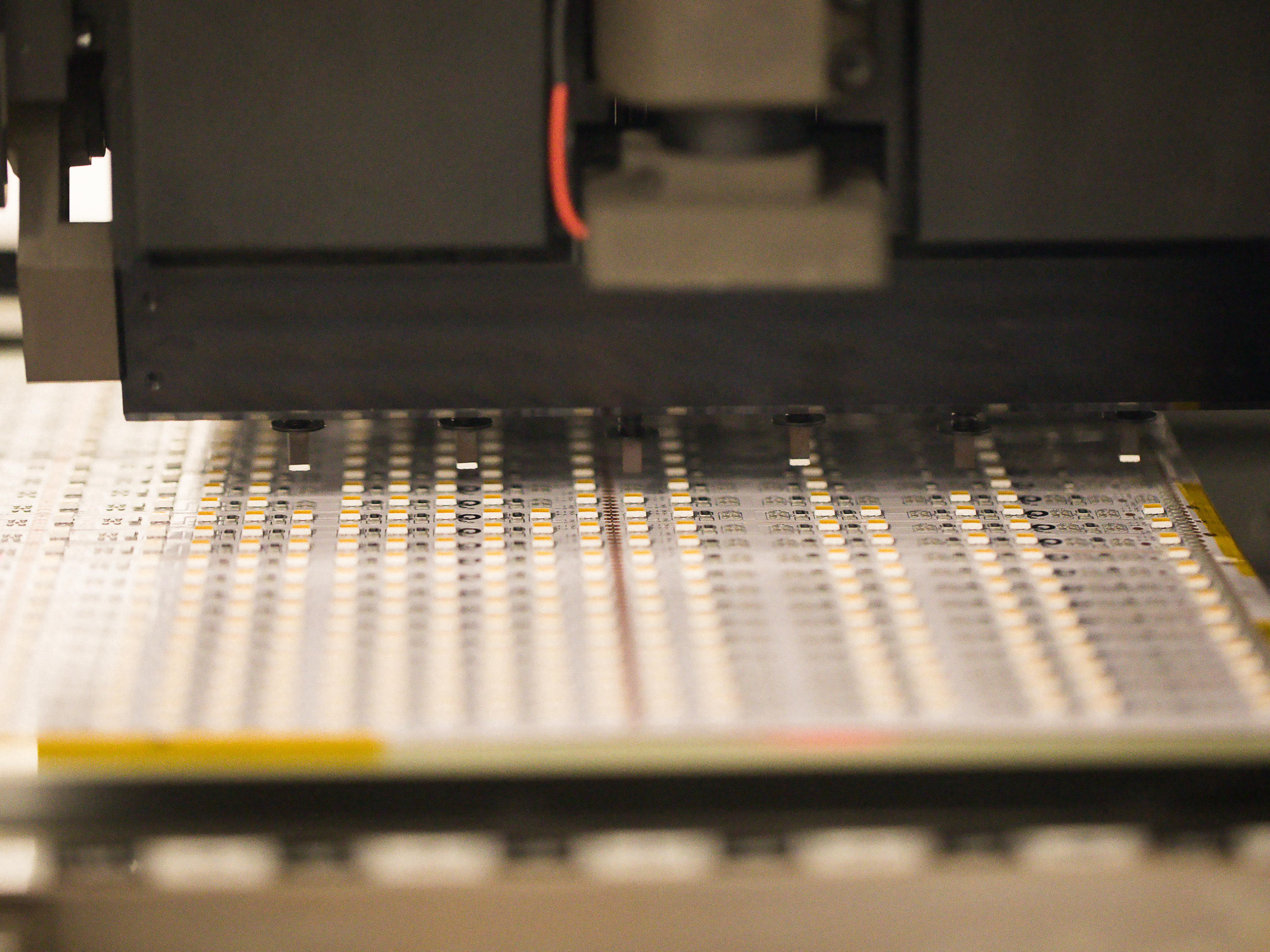

In the manufacturing process, LED diodes are mounted on a substrate that house the electronics (diodes) and power (resistors). On the underside, a double face tape is adhered to the back of the substrate for ease of mounting - thus the common name of "tape" for the product.

Cut points vary among manufacturers from anywhere between 1" to 6" or more. Every cut point adds complexity and cost in the manufacturing process. This is why some manufacturers will choose to spread them out to minimize production costs in order to offer lower-priced products. So what does this all mean, exactly?

The Shorter the Cut Point, The More Uniform The Light

The cut points are an important factor in a linear LED fixtures performance when installed. When an application does not have perfect measurements designed around the specific cut point, this leads to large dark ends on certain runs.

For example, a run of 4' 3" with a 4" cut-point will have approximately 1.5" of darkness at each end. If that were a 6" cut point, the dark space would be the same. By contrast, a 2" cut point would leave a dark space of ½" of darkness per end. A 1" cut point would offer full and even illumination across the entire application.

1" LED Cut Points Minimize Dark Spots

Kitchen cabinetry is a popular millwork application for linear LED lighting: in, above, under cabinet and toe kick lighting. There are a variety of standard cabinet sizes and many custom cabinets built to fill a specific space and the measurements inside of a cabinet can differ from the under and upper cabinetry.

Though a dark space of 1.5" does not sound like much, it can be highly visible based on the application. If the under cabinet lighting is installed directly above a highly reflective countertop, you will see the dark spaces on either end as you look at the countertop.

The same is true when uplighting a bright ceiling above the cabinets. The smaller the dark space, the more uniform the lighting will appear between cabinets of different sizes. This may only be reference to one application, but these basic principles are similar in other linear applications like cove, linear recessed, linear surface, millwork, and perimeter lighting.

The shorter the cut point, the more uniform the light will appear no matter what the overall length will be. A 1" cut point limits the dark end to ½" or less, and a 2" cut-point limits that dark space to less than 1". Anything above 2'" can have dark spaces of 1.5" or more.

0 Comments: