3 Optical Factors to Consider When Choosing An LED Fixture

This may be news to some, as it certainly was to us when we entered the world of architectural LED lighting some 8+ years ago. Here's the truth...

LED Lenses Are NOT Created Equal

As a power supply company steeped in integrity and altruism, we've always been dedicated to producing the highest-quality products for the design community; quality never to be compromised by price point.

It was only natural for us to think that those who claimed to have the the same quality standards possessed the same level of integrity. Needless to say, we were wrong. While many look the same, LED optical performance and lens quality varies vendor to vendor, manufacturer to manufacturer.

One of the biggest discoveries made was of the type of optic lenses that didn't meet our level in quality standards. The results were alarming. They not only failed to deliver the same light output, but didn't preserve the light engine's color properties either. This change didn't just occur from one type of lens to the next; but from the "same lens" used on various-sized extrusions and profiles.

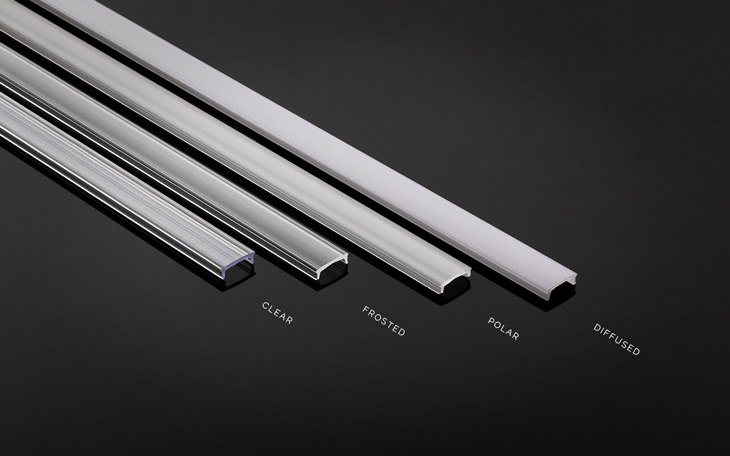

3 Factors to Consider When Choosing Linear LED Fixture Lens:

- Type of Lens Material

- Material Quality - UV stability, durability, flexibility

- Optical Performance - lumen output, preservation of LED strip color properties

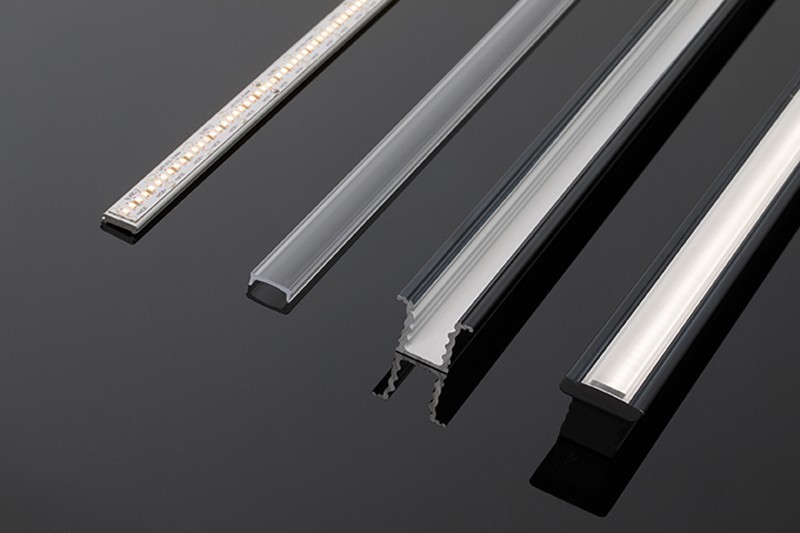

The Type of Lens Materials Can Affect Optical Performance

Lenses are typically made from either polycarbonate, acrylic, or a combination of the two. Each has their own particular advantages and disadvantages when it comes to the quality of light output and performance.

Polycarbonate vs. Acrylic

With polycarbonate, you get a very flexible lens that is generally hard to break. However, the light output quality through this type of lens is suspect at best. It's not UV stabilized, so in both direct and indirect sunlight the lens will eventually become brittle and yellowed.

A combination of polycarbonate and acrylic materials do help with these factors, but you may find that the lens becomes more fragile, due to the stiffness in the acrylic. The light output from this combination is slightly better, but still not the greatest. Additionally, many manufacturers add whitening agents to their lens formulas as a way to hide the LED diode imaging, which may yield undesirable results.

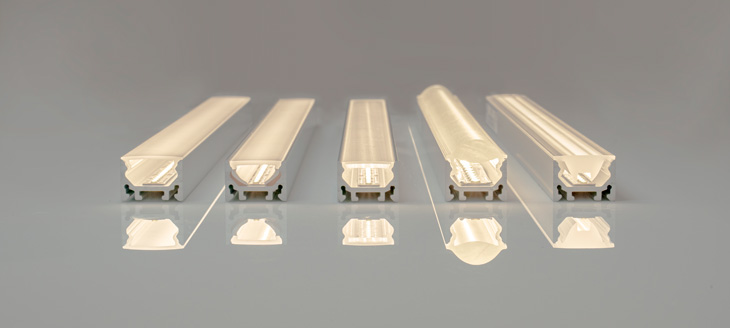

Q-Tran's Proprietary Lens Formula

At QTL, we've developed a custom acrylic lens formula that provides clients and customers with the best light output possible while delivering the most lumen output.

- Flexibility and Durability - minimizes the chance of breakage

- UV Stability

- Scratch Protection

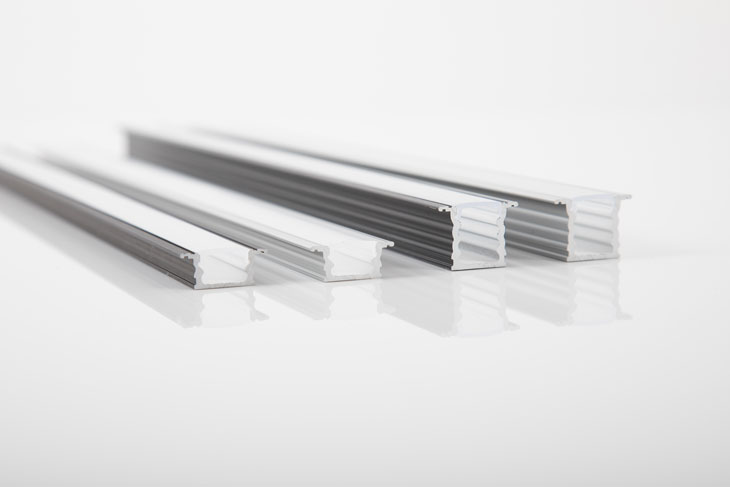

- Ease of Compatibility with QTL's Line of Extrusions

- Consistency in Diffuseness

- Preservation of Color Properties

- Diode-Free, High Lumen Output

Our Photometric Data Reveals All

While most companies fail to provide the photometric data in support of their "quality" products, we pride ourselves in the fact that we do! Our photometric data is readily accessible to you any time of day; just visit our technical downloads web page for immediate access.

We strive to provide the best architectural led lighting solutions in the marketplace and hope in by using our products, you will see that not all optic LED lenses, or products even, are created equally.

0 Comments: